Difference Between BONDED and PVC Coating

FUSED AND THERMALLY ADHERED (FUSED BONDED)

Meets ASTM F668 CLASS 2B

This process is an atmospheric or baked-on application. The steel core wire is heated, and then adhesive (or primer) is applied. The heated steel travels into a machine containing the PVC; at this time the PVC is in a very fine powder state, air is blown into the machine, which causes the PVC powder to circulate. When the heated steel (with the adhesive) comes in contact with the PVC, the PVC melts or fuses onto the adhesive (primer). The vinyl coating thickness is .006 - .010 inches at any point (7 mils).

EXTRUDED (EXTRUDED BONDED)

Meets ASTM F668 CLASS 2A

This process is a pressurized application. The steel core wire is coated with adhesive (glue) and then it travels into a machine containing the PVC. The vinyl material (PVC) is in a plastic, hard state. As the steel travels through the machine, the PVC is melted and compressed onto the heated adhesive under 5000 lbs of pressure, thus creating a dense and impervious covering. The vinyl coating thickness is .015 - .025 inches at any point (22 mils).

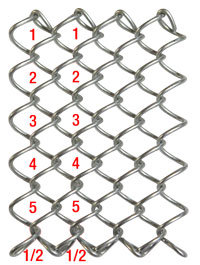

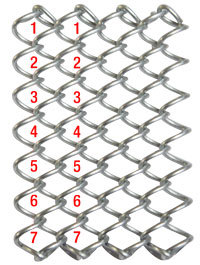

How to Measure Mesh size

Measure your chain link fence diagonally (inside measurement) as shown in the picture above.

How to Count Diamonds

1/2 DIAMOND

FULL DIAMOND